New Arrival!!! Saga Digital Sheet Die Cutter with Optical sensor SC30II

2022-05-05

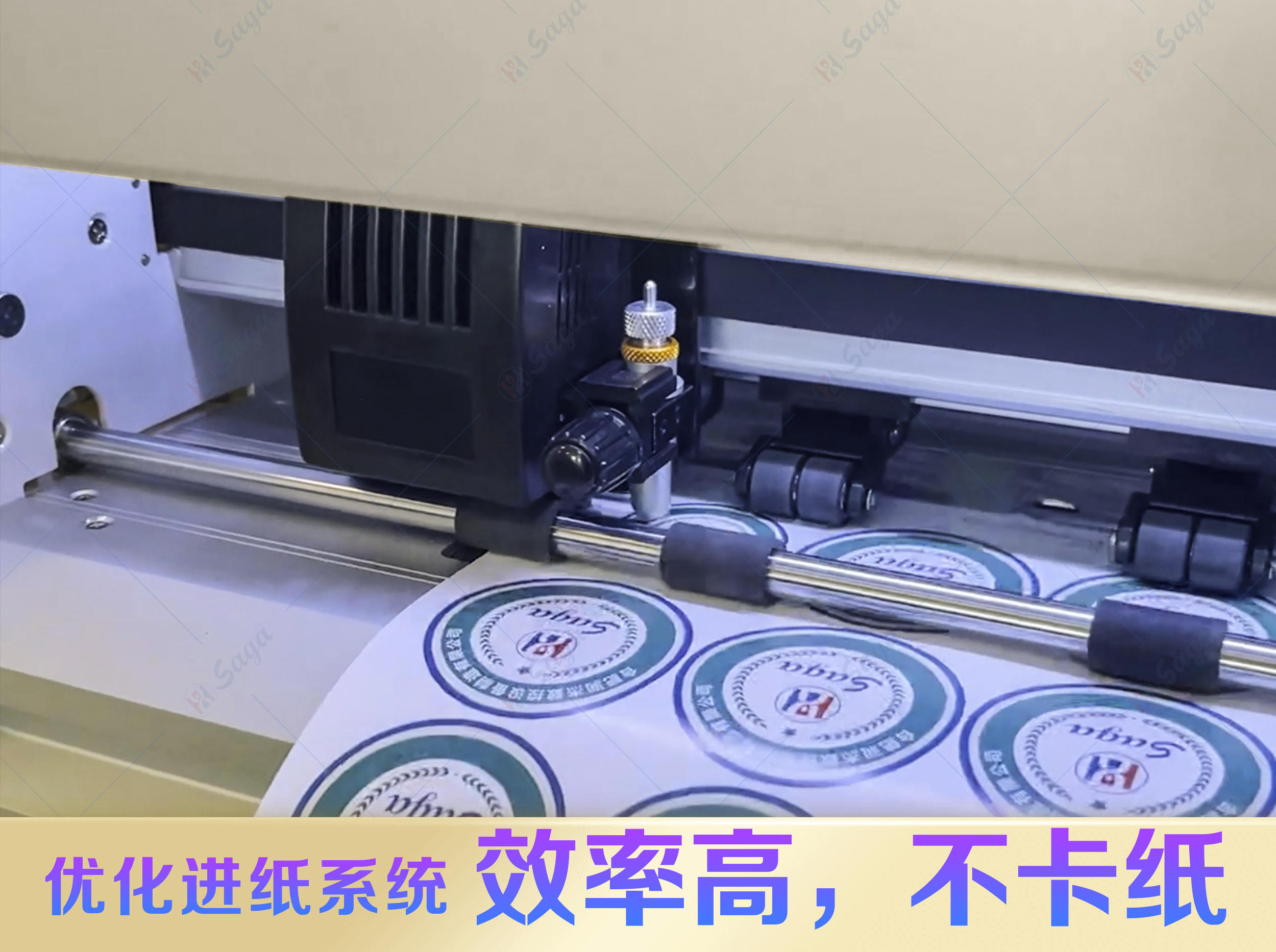

We Sagacnc Updated our SC series -SC30 on April 2022

Main Features : SAGA's sheet cutter cuts paper up to 480mm x 330mm and accurately positions the paper. It can feed 50 sheets at a time (according to the thickness of the paper). A wide range of printable self-adhesive materials are available, with a maximum contact pressure of up to 500g and a maximum cutting speed of up to 500mm/s, and the ability to mix cutting materials with different materials. SAGA's sheet cutter is the ideal equipment for many business areas such as copy shops, product labels, and office applications. 1. The maximum cutting area is A3+ (483mmX330mm),catering to market demands perfectly 2. Optimized auto feeding system, more efficiency and no jam 3. Auto-recognition of registration marks guarantees scanning and cutting accuracy

with more convienent mutiple input methods

we add wifi to get rid of the shackles of the harness

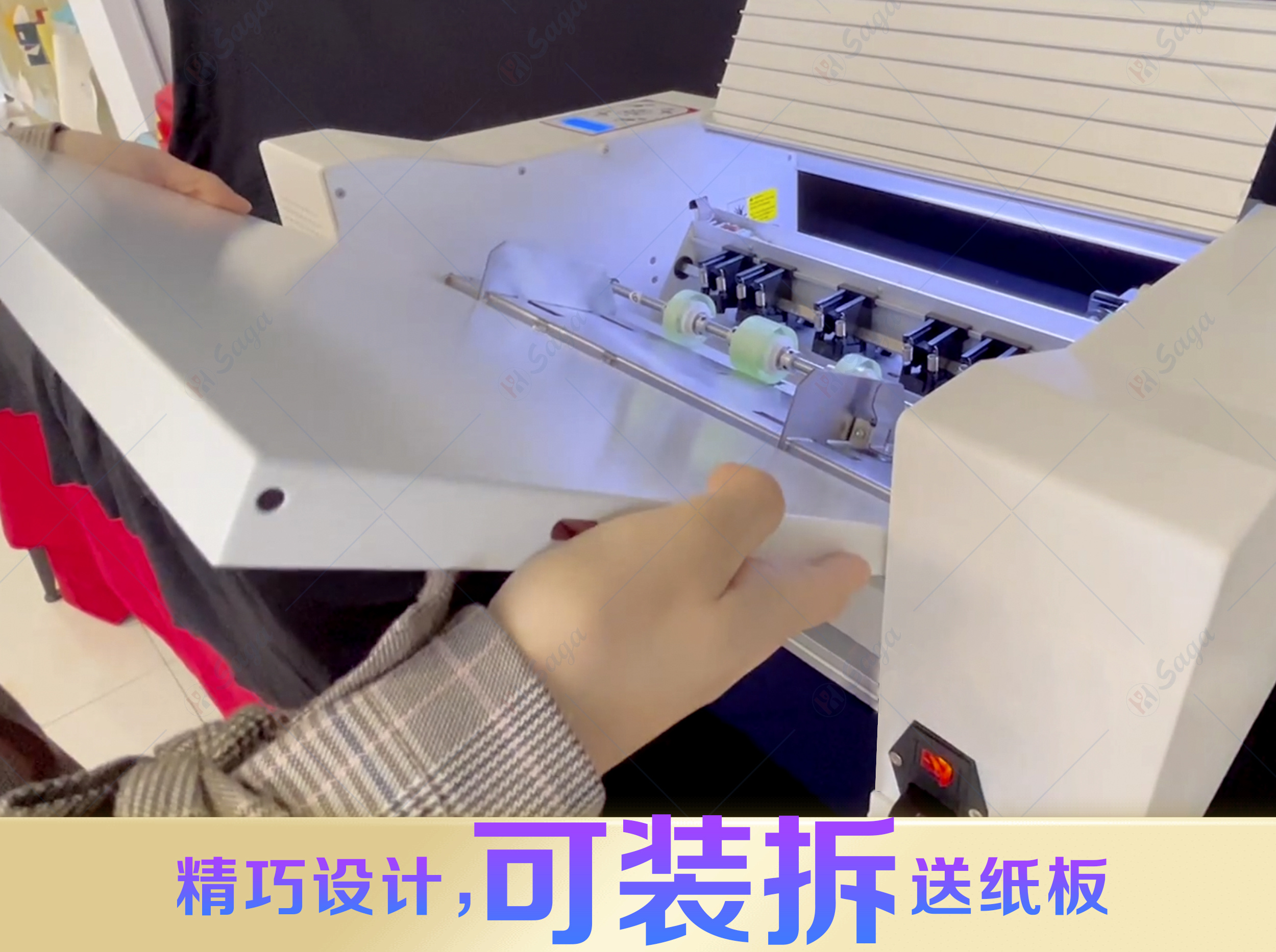

Advanced sheet feeding system ,more effeiciency with no jam Clever design assemble feedingboard

Clever design assemble feedingboard

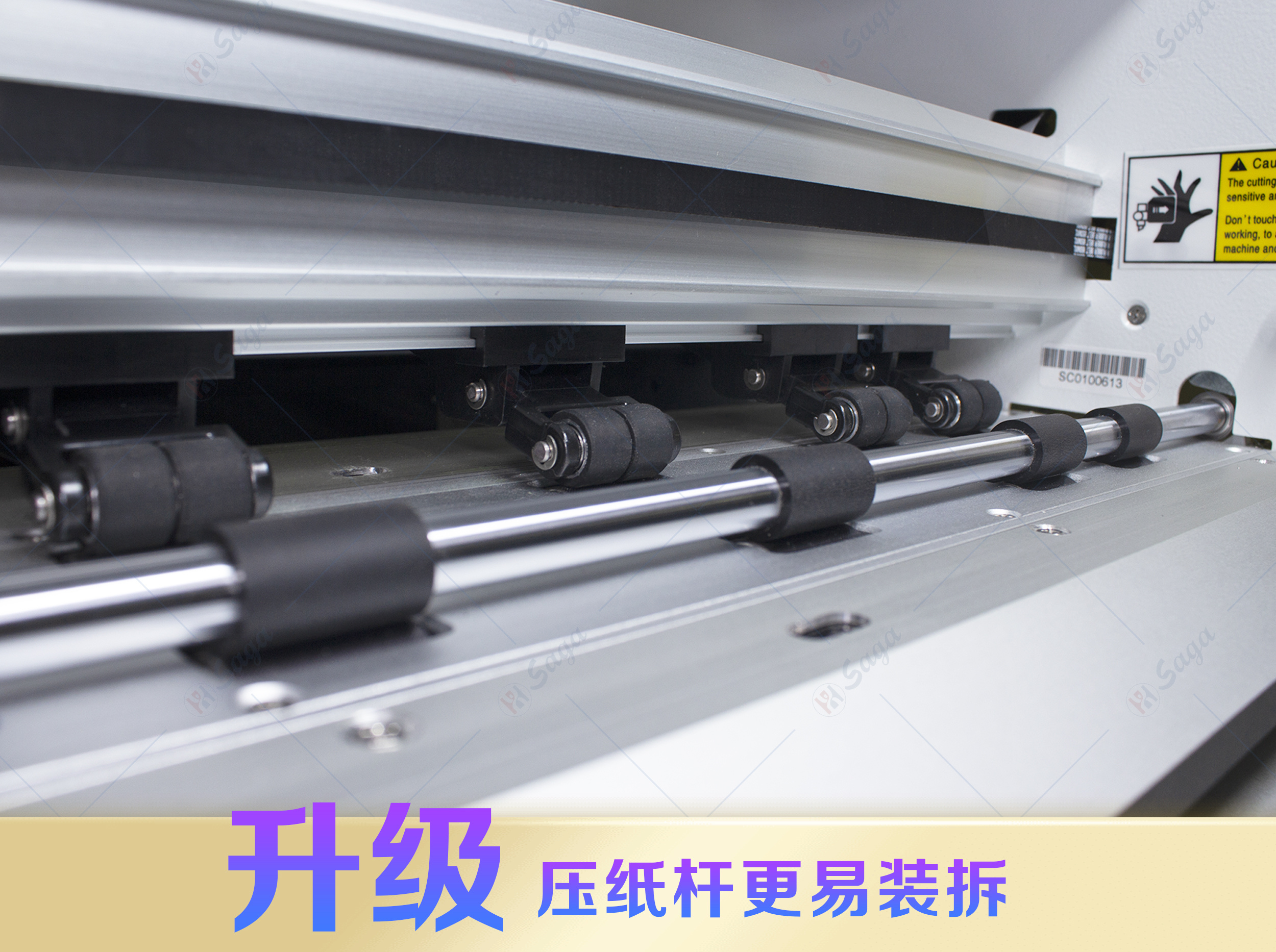

Upgraded paper bail, more easily to assemble

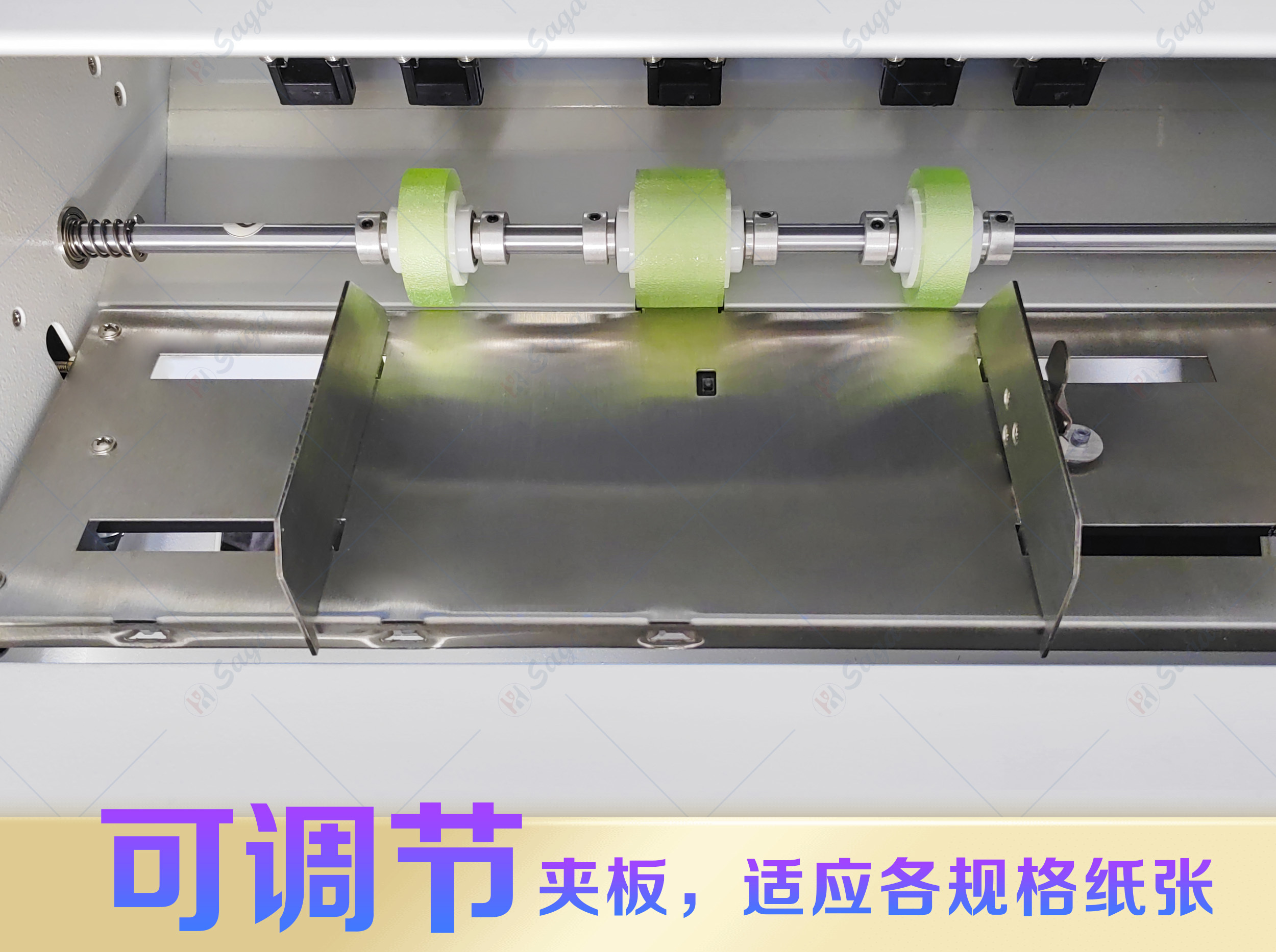

Adjustable splint, suit for sheet size under 330mm*483mm

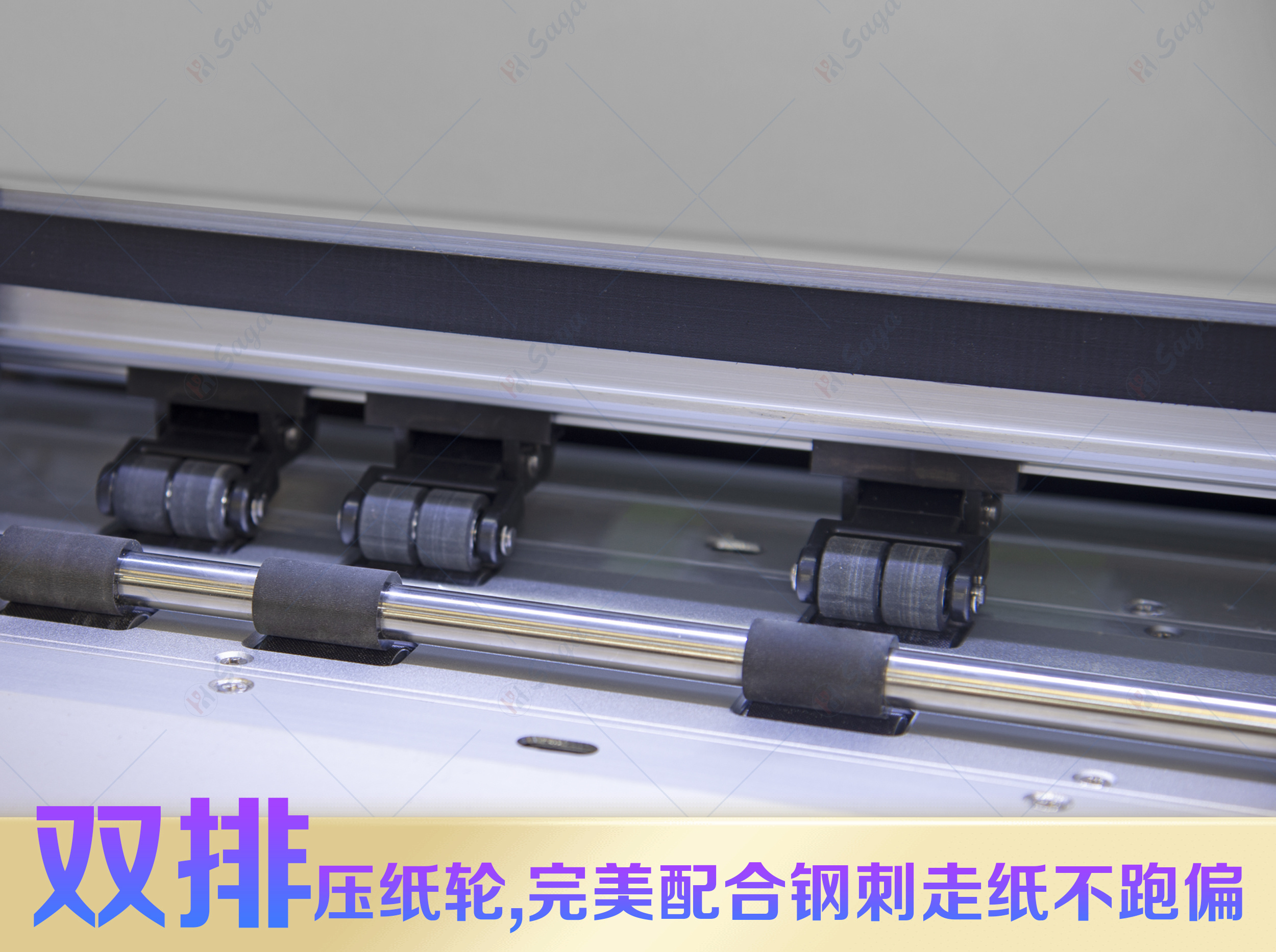

Double roll bail roller, perfect with pinch roller no astray

sales@sagacnc.com

sales@sagacnc.com +8618019542581

+8618019542581 +8618019542581

+8618019542581